WEAVING HUTS AND EQUIPMENT

FOR LIVICHUCO COMMUNITY, ORURO, BOLIVIA.

The project

Livichuco, a small community of some 30 families situated in the highest zone of ayllu Qaqachaka (in Avaroa province, Oruro department, Bolivia) makes its living by herding llama, alpacas, and sheep, supported by some potato and onion cultivation, permitted by the change of climate in recent decades.

The men tend to travel outside the agricultural season while the women remain in the community herding and weaving. The village is characterised by its straight main thoroughfare, a result of being a tambo waystation in centuries past.

The men tend to travel outside the agricultural season while the women remain in the community herding and weaving. The village is characterised by its straight main thoroughfare, a result of being a tambo waystation in centuries past.

The local weaving association APSU (“Handiworks to continue together”, in Spanish “Artesanías para seguir unidos”) was formed in the early 1990s to rescue natural dyes and traditional weaving practices in the face of rampant modernisation. They soon needed a large meeting room, spaces for weaving for their 50 members, and an outdoor site where they could experiment with natural dyes.

This project, centred in the building of two weaving huts in a new compound that APSU had obtained, was completed in December of 2000, during a very difficult period in Bolivia’s recent history, of economic crisis, and constant uprisings and road blockades. The project cost about $US 8000 (£4000) of which some $6000 was spent on the construction of the two huts and associated deposits, and the rest on looms, and the equipment in looms and carpentry materials for the school workshops.

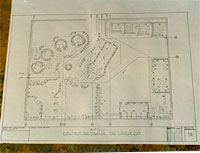

The original design was elaborated in consultation with our clients in APSU, in a series of easy to understand drawing and models

At first we planned an open sided weaving shed for the women, with a wind-down plastic sheet. However, a particularly fierce period of rains during 1998-1999, coaxed the APSU women to opt for a completely enclosed hut, so that they could weave inside when it rained. This entailed the cost of extra flooring materials, two large timber windows and a large double door, with all the extra transportation costs involved. However, the large windows proved to be very satisfactory for the activity of weaving inside

At first we planned an open sided weaving shed for the women, with a wind-down plastic sheet. However, a particularly fierce period of rains during 1998-1999, coaxed the APSU women to opt for a completely enclosed hut, so that they could weave inside when it rained. This entailed the cost of extra flooring materials, two large timber windows and a large double door, with all the extra transportation costs involved. However, the large windows proved to be very satisfactory for the activity of weaving inside

Both the women’s and men’s sheds have traditional thatched roofs, augmented with wire meshing as we use in England, so that the thatching lasts longer. To date the roofs have lasted some seven years quite satisfactorily.

The enclosed space of the women’s hut quickly prompted some technological innovations in loom design, from the traditional wooden frame looms which have to be staked into the earth, to metal-framed looms heavy enough to settle on the new solid floor inside the hut. They innovations were fascinating to witness, as the APSU members experimented with different prototypes. ILCA finally designed a prototype metal-framed loom, with moveable pegs to allow better tensioning; its use has now spread throughout the whole ayllu. In all, five modern metal looms were installed for the women to weave mantles inside their hut when the weather is cold and rough outside.The weaving shed for the men was designed with the same large windows at the front but special lighting at the back so that the men could work on three wooden upright Spanish looms situated in bays, for weaving rustic cloth (called in Spanish bayeta), rather like tweed, and heavy mantles and blankets.

The enclosed space of the women’s hut quickly prompted some technological innovations in loom design, from the traditional wooden frame looms which have to be staked into the earth, to metal-framed looms heavy enough to settle on the new solid floor inside the hut. They innovations were fascinating to witness, as the APSU members experimented with different prototypes. ILCA finally designed a prototype metal-framed loom, with moveable pegs to allow better tensioning; its use has now spread throughout the whole ayllu. In all, five modern metal looms were installed for the women to weave mantles inside their hut when the weather is cold and rough outside.The weaving shed for the men was designed with the same large windows at the front but special lighting at the back so that the men could work on three wooden upright Spanish looms situated in bays, for weaving rustic cloth (called in Spanish bayeta), rather like tweed, and heavy mantles and blankets.

Careful use of funds, and the considerable counterpart of manual labour provided by APSU men and women allowed us to build two additional deposit buildings, for the storage of textile materials and products.

Fax: La Paz (00 591 2) 2 419661 - Correo Electrónico: ilcanet@ilcanet.org